Paper is part of your life in the most important moments, either to write something down, record, plan, read or learn, besides telling the best stories. Check out our tips on how to take good care of paper.

Some tips on how to get the best of paper

Choose the format and grammage (options)

Choose the format and grammage (options) Use the correct side of the sheet

Use the correct side of the sheet

(seal in the packaging saying: print this side first) Be careful about humidity

Be careful about humidity

(store in closed packaging) Do not ventilate reams

Do not ventilate reams Do not use drying oven

Do not use drying oven

Care with storage and handling

Maximum 3-pallet piling

Maximum 3-pallet piling Do not place boxes directly on the floor

Do not place boxes directly on the floor Leave pallets with a minimum 40-cm distance from the wall

Leave pallets with a minimum 40-cm distance from the wall When transporting boxes, carry them by the straps, never by the band

When transporting boxes, carry them by the straps, never by the band When transporting in vehicles, make sure the load is secure and safe to avoid damages to the paper

When transporting in vehicles, make sure the load is secure and safe to avoid damages to the paper Inform tracking codes in case of malfunctions and/or manufacturing defects

Inform tracking codes in case of malfunctions and/or manufacturing defects

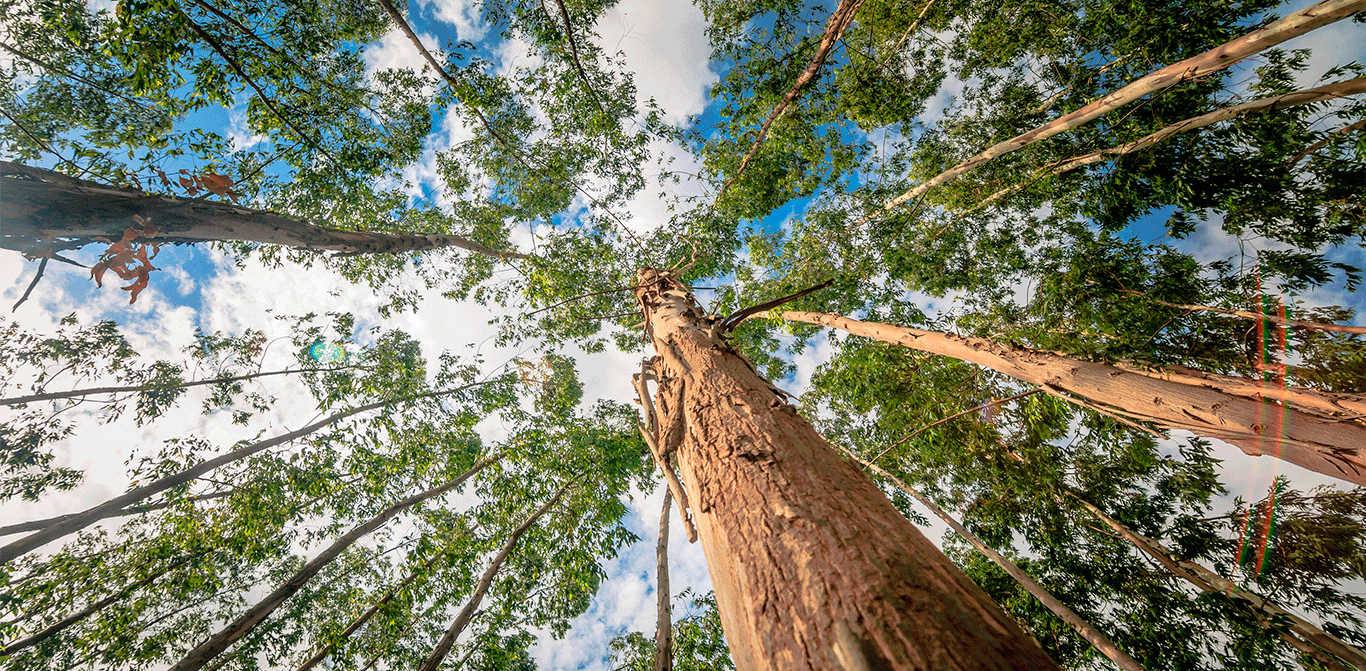

Benefits that go beyond paper

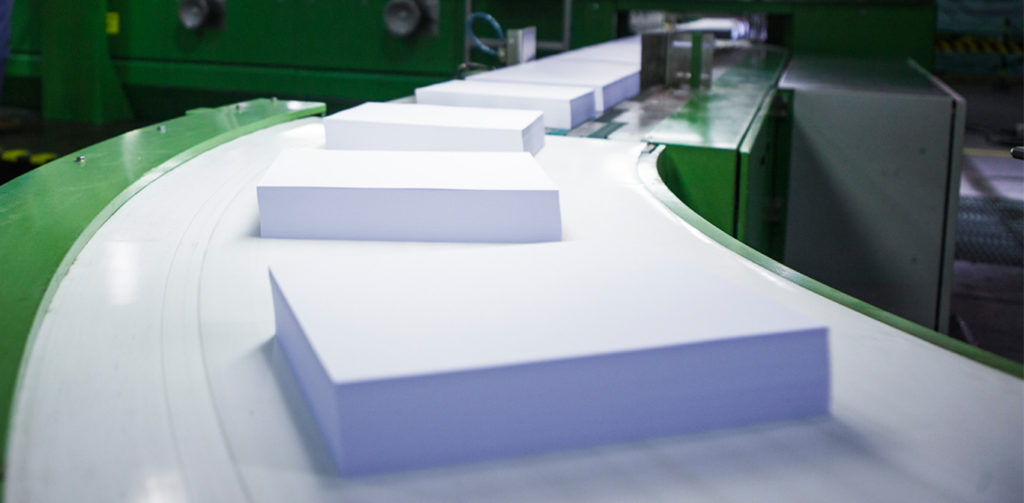

100% recyclable packaging

100% recyclable packaging The only one with easy opening system

The only one with easy opening system 99.99% of no paper jam guaranteed

99.99% of no paper jam guaranteed No multiple sheet paper feeding in the printer guaranteed *

No multiple sheet paper feeding in the printer guaranteed *

Excellent quality of sheet cut, specification for the format dimensions smaller than that required by INMETRO. Perfect sheet angles (paper alignment).